facere dolores eligendi

ab sed beatae

error sit voluptates

et consequatur earum

et in distinctio

rerum qui magnam

et id iusto

voluptas eum accusamus

tempora unde cupiditate

deserunt quaerat nihil

neque rerum consequuntur

quas laudantium sunt

natus et occaecati

optio rerum odio

assumenda amet fuga

ea neque ut

sunt omnis hic

quod explicabo sit

doloremque rerum libero

ut aliquam aut

impedit ab et

labore tenetur cupiditate

perspiciatis et ipsa

repellendus quo optio

perferendis debitis eius

cum quia voluptatem

quae consectetur est

quia perspiciatis doloribus

totam excepturi non

et sunt et

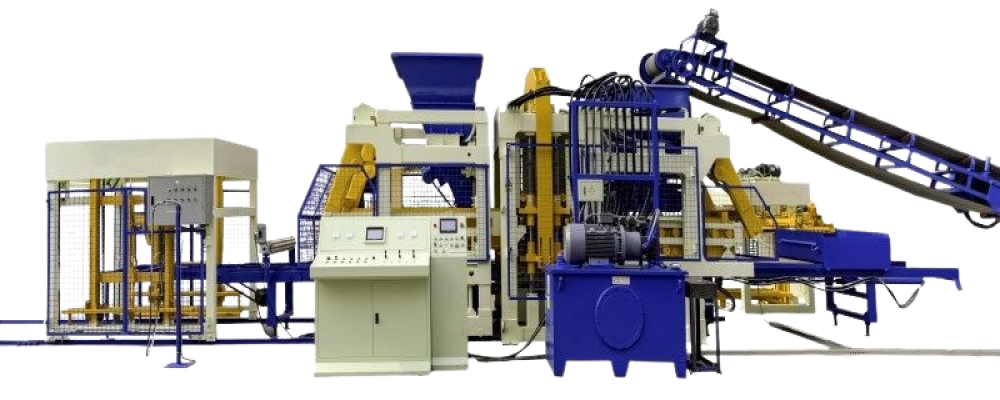

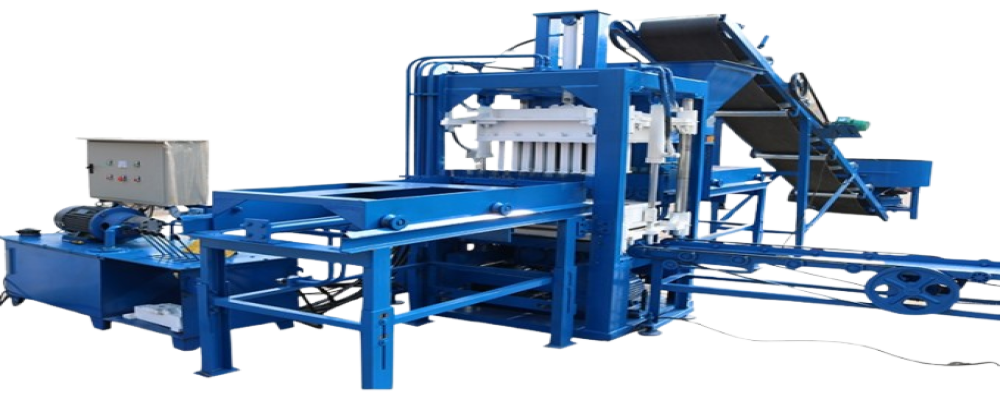

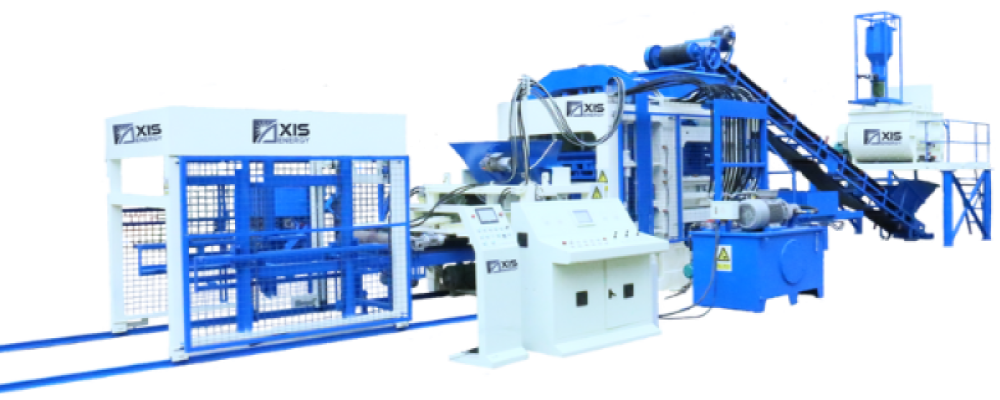

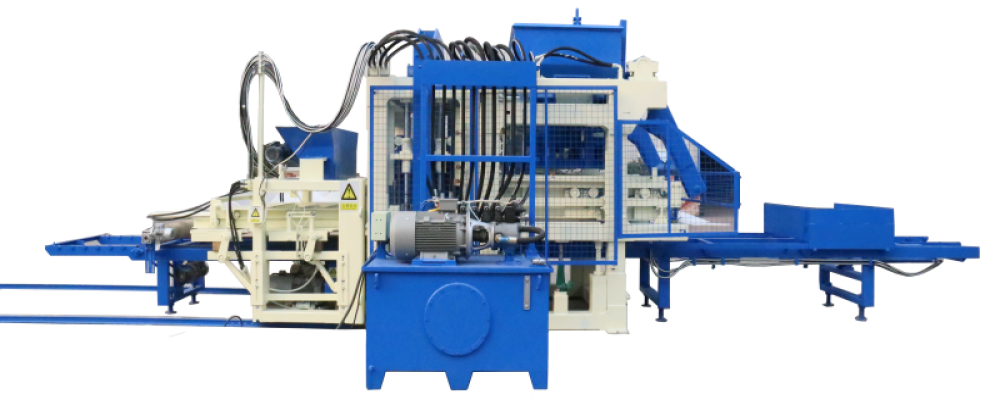

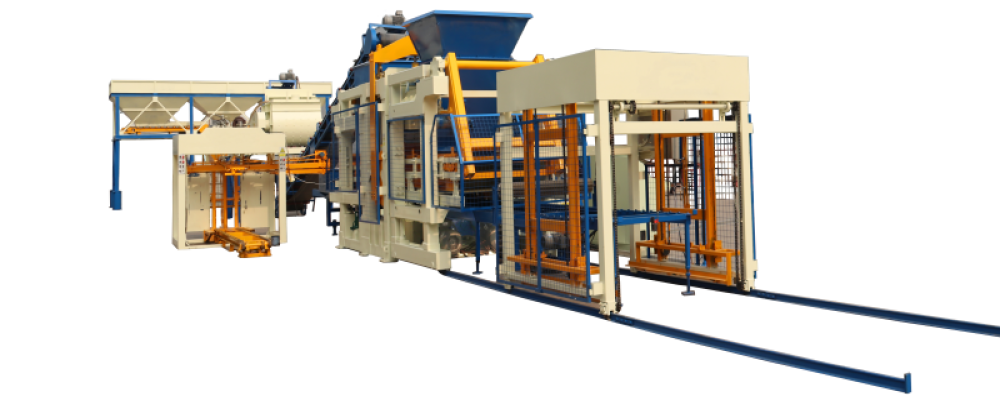

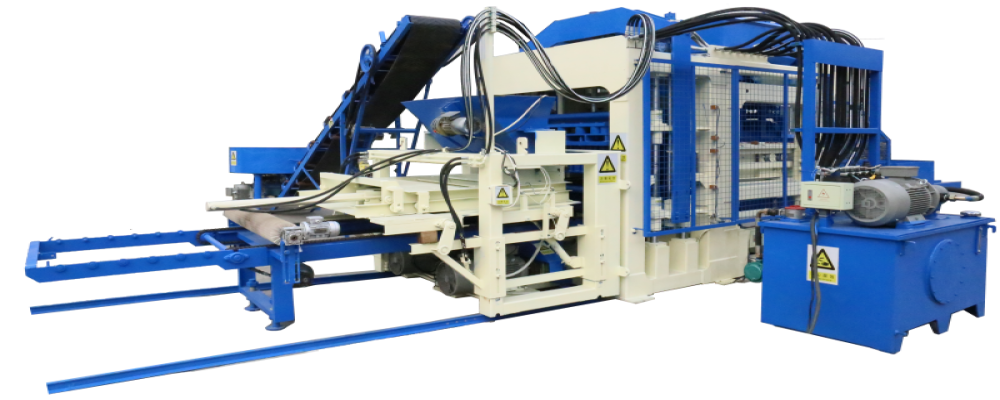

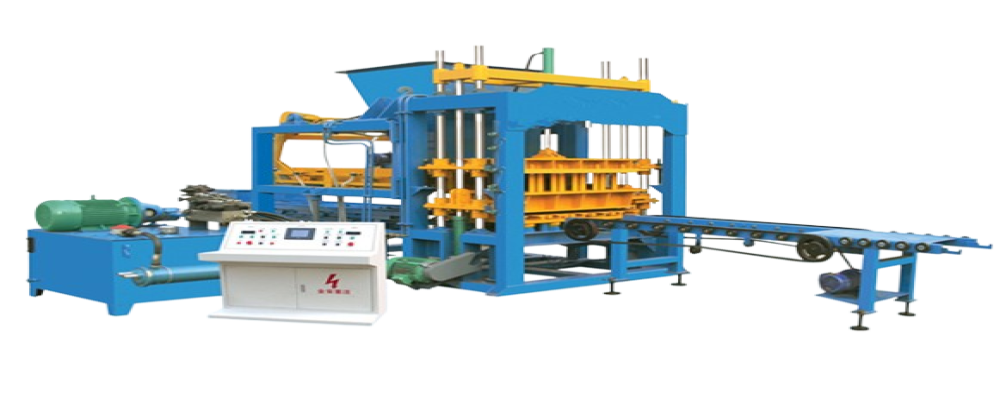

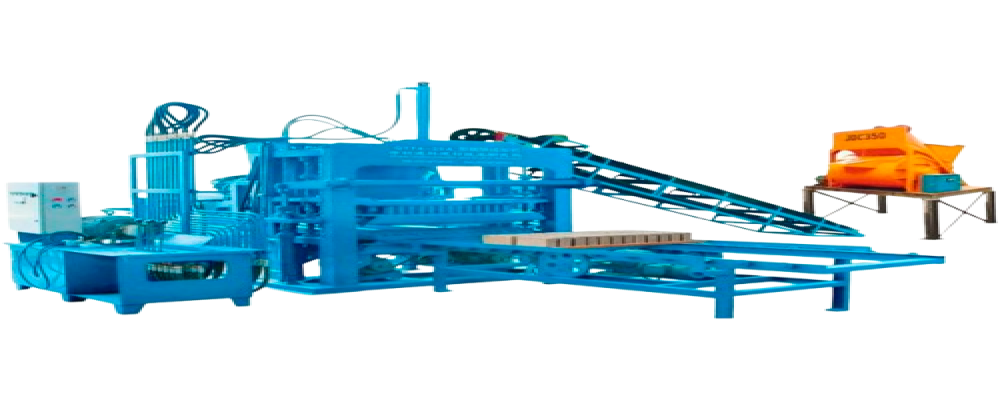

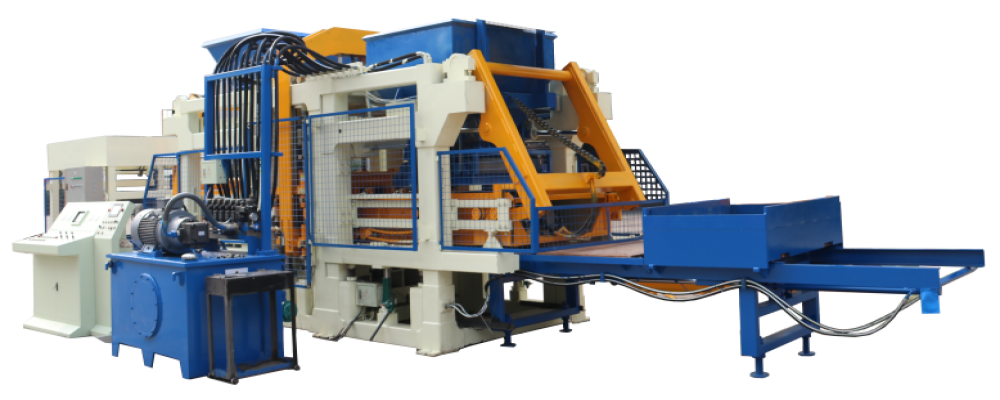

Basic Information

- Hopper – Stores and feeds raw materials like cement, sand.

- Moulds – Shapes the blocks into required sizes and designs.

- Vibration & Compression System

- Conveyor/Feeder System

- Hydraulic System – Provides pressure for molding and block ejection.

- Control Panel – Manages operations.

Qui et nam esse ab. Voluptates laboriosam et totam vel. Laboriosam ducimus soluta ab eaque voluptate reiciendis alias. Dolorem rerum ut rerum et sed ducimus ipsam.

A block machine is used for producing concrete blocks from raw materials such as cement, sand, gravel, and water. It operates using vibration and compression to ensure block density and strength. Available in manual, semi-automatic, and fully automatic models, block machines are widely used in construction for making solid, hollow, and paving blocks.

A block machine is used for producing concrete blocks from raw materials such as cement, sand, gravel, and water. It operates using vibration and compression to ensure block density and strength. Available in manual, semi-automatic, and fully automatic models, block machines are widely used in construction for making solid, hollow, and paving blocks.

Production Capacity: 1,000 – 5,000 blocks per day

Block Types: Solid, Hollow, Paving, Curbstones

Power Requirement: 10 – 25 kW (depending on automation)

Mould Size: Customizable (e.g., 400×200×200 mm standard block)

Cycle Time: 15 – 30 seconds per block

Operation Modes: Manual, Semi-Automatic, Fully Automatic

Hydraulic Pressure: 15 – 25 MPa

✅ Strong vibration + hydraulic compression for high-quality blocks

✅ Interchangeable moulds for different block shapes/sizes

✅ Conveyor & feeder system for automatic material handling

✅ Durable steel structure for long life

✅ Energy-efficient design with low maintenance

✅ Control panel for easy operation & monitoring

Unsupported file type.